Customer Visits

Under the scorching sun, Hangzhou Vulcan Factory welcomed waves of guests. Many semiconductor industry customers came to Vulcan Factory for visits and business communications. Hangzhou Vulcan's senior executives and core team members gave them a warm reception.

The visiting customers further understood the production and manufacturing process and technology of Vulcan products through a field visit to Vulcan Factory. At the same time, Vulcan members conducted detailed and in-depth exchanges and discussions on the company's current technology research and development, product production, project delivery, etc., to meet industry challenges together and create the future of semiconductors together.

Shanghai Xinsheng team visited and guided & visited

Tianke Heda team visited and guided & visited

Product introduction

At present, after technical iteration, Vulcan has launched two new hard felts for the semiconductor industry: high-purity viscose-based long-fiber hard felt and high-purity viscose-based short-fiber hard felt.

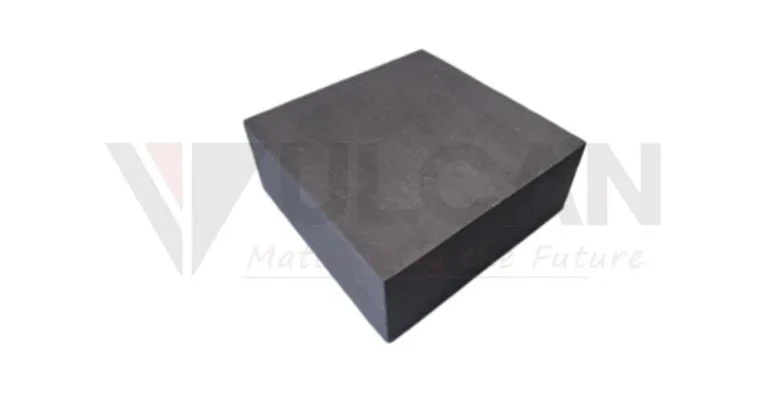

High-purity viscose-based long-fiber hard felt

·Excellent thermal insulation performance

·High mechanical strength

This product was originally developed for large silicon wafer semiconductor industry and has been verified in silicon carbide semiconductor, sapphire and other fields. Compared with Japanese imported materials, Vulcan Technology's long-fiber hard felt has better thermal insulation performance and service life, and can also provide corresponding replacement models in conjunction with customers' existing processes. According to customer needs, various composite structures such as graphite coating, pyrolytic carbon, graphite paper, carbon cloth, etc. can be made to meet various complex thermal field requirements.

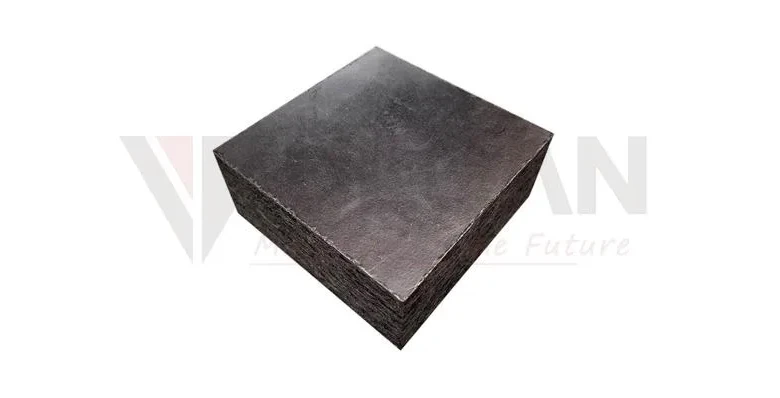

High-purity viscose-based staple fiber hard felt

·Short fiber dry molding

·Isotropic network structure

High thermal insulation, high purity, long service life, unique formula and process design, strict quality control, and a series of performances have reached the international advanced level. Mainly used in high temperature environments under vacuum or inert gas protection, such as SiC induction furnace/resistance furnace, silicon single crystal/polycrystalline furnace, high temperature sintering furnace, optical fiber rod making/drawing tower, thermal high temperature furnace, etc., especially suitable for electromagnetic induction furnace.

Future Vision

In the future, Vulcan will continue to adhere to the concept of "materials change the future", and through continuous innovation, create value for customers and save costs; adhering to the concept of open cooperation, work hand in hand with partners from all walks of life to create a better future!

Vulcan New Material Technology Co., Ltd. is a high-tech enterprise focusing on the research, development, production and sales of high-purity graphite, carbon fiber high-temperature thermal field materials and new carbon material products. At present, the company's products have been widely used in domestic semiconductor silicon wafer crystal growth, SiC crystal growth, photovoltaic crystal growth, high-end metallurgy & industrial furnaces, optical fiber preforms & optical fiber drawing, sapphire crystal growth, ion implantation, MOCVD and other industrial fields, and can provide customers with thermal field application technology services and solution design.