On April 25, the two-day CFE2024 China Flow Battery Energy Storage Conference officially opened in Hangzhou.

Exhibition site

At present, the high-performance flow battery electrode felt and graphite bipolar plate products of Vulcan Technology have been applied in the all-vanadium flow battery systems of many flow battery customers. The on-site staff introduced the product uses and characteristics in detail to the visitors, and also had in-depth exchanges with many customers and reached many new cooperation intentions.

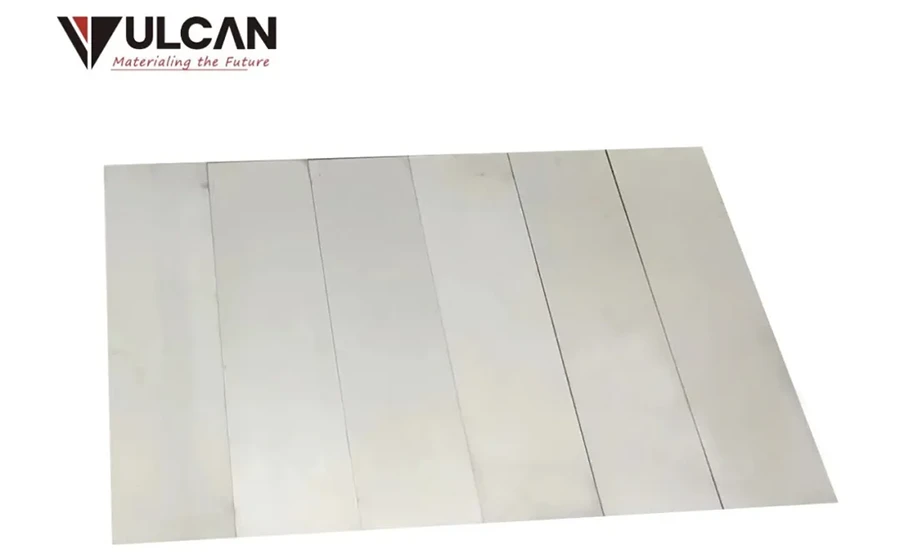

Latest Products

[Liquid Flow Battery Electrode Felt] As the electrode material of all-vanadium liquid flow battery, it has an important impact on the performance and cost-effectiveness of liquid flow battery.

Process: Vulcan uses continuous equipment to process and produce liquid flow battery electrode felt, which is made of polyacrylonitrile pre-oxidized fiber through special needle weaving, high-temperature carbonization and graphitization, and finally activated.

Features: The electrode felt of the Vulcan flow battery has a flat surface and uniform thickness. It has the characteristics of small internal resistance of the battery stack, good electrochemical activity, good corrosion resistance, low battery stack cycle attenuation, high energy efficiency, etc., and the thickness is controllable. There are multiple thicknesses of 2.5-5.0mm to choose from. At the same time, Vulcan Technology has a professional R&D team and laboratory, which can actively cooperate with customers to adjust performance.

The main function of [graphite bipolar plate] is to collect and conduct the current generated during the battery charging and discharging process, provide support for the membrane and electrode, and connect and separate multiple batteries in series.

Process: The graphite bipolar plate of Vulcan is made of high-purity isostatic graphite. Compared with ordinary graphite, it has a fine and dense structure, good uniformity, and isotropy. Therefore, it has uniform conductivity and is the best choice as an electrode material for acid flow batteries.

Features: Vulcan presented two electrode products at this exhibition, graphite bipolar plate and hard graphite bipolar plate. The minimum processable thickness of graphite bipolar plate is 0.8mm, and the resistivity is 1.03mΩ·cm. The hard graphite bipolar plate is further processed on the graphite surface, and its resistivity can be reduced to 0.66mΩ·cm, which has better conductivity.

Future Vision

In recent years, urban electricity consumption has increased year by year, which has put forward higher requirements for energy supply methods and new power systems, and energy transformation and reform have continued to upgrade. With the continuous introduction of energy storage policies, liquid flow battery energy storage, as one of the most promising seed players in new energy storage and long-term energy storage, will have a very broad market in the future, and its industrialization, scale and commercialization will also enter an accelerated stage. Vulcan Technology will also follow the development trend of the industry, improve technology, strengthen innovation, fully cooperate with the majority of energy storage companies, optimize and upgrade product performance, and work together with upstream and downstream industries to promote the development of the liquid flow energy storage industry!

Vulcan New Material Technology Co., Ltd. is a high-tech enterprise focusing on the research and development, production and sales of high-purity graphite, carbon fiber high-temperature thermal field materials and new carbon material products. At present, the company's products have been widely used in domestic semiconductor silicon wafer crystal growth, SiC crystal growth, photovoltaic crystal growth, high-end metallurgy & industrial furnaces, optical fiber preforms & optical fiber drawing, sapphire crystal growth, ion implantation, MOCVD and other industrial fields, and can provide customers with thermal field application technology services and solution design.