Overview

Vulcan Technology is a high-tech enterprise focusing on the development and production of high-end thermal field materials.

- Product

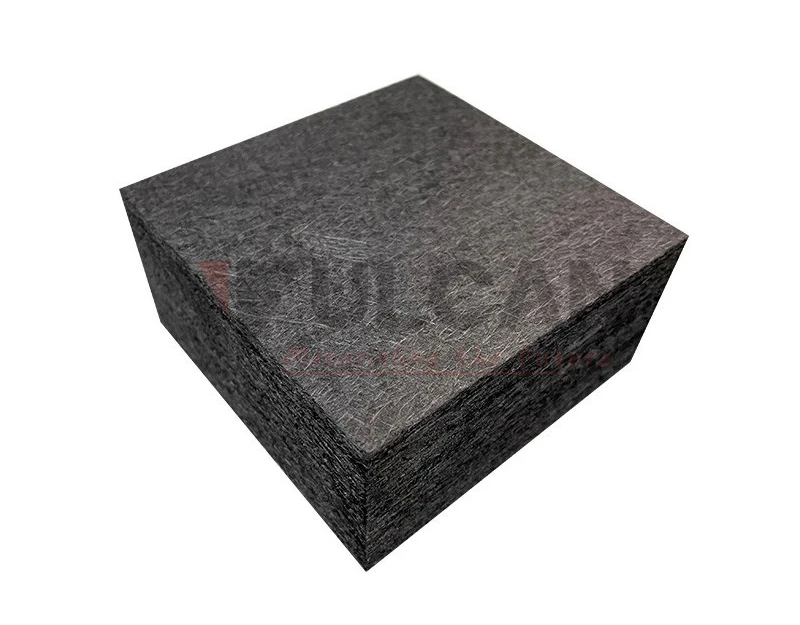

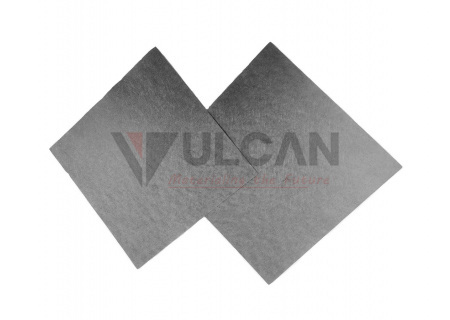

- Carbon fiber soft felt Carbon fibre composite rigid felts (long and short) C/C Composite structural materials High purity graphite High performance coating materials Other